- Toner Canon 118 Yellow Original

- Fuji Xerox Toner Yellow High (CT350488)

- Tinta Hp 933XL Yellow Original

- Tinta HP 27 Black Original

- Toner HP Laserjet 49A Black [Q5949A] Original

- Toner HP Laserjet Black 53A [Q7553A] Original

- Toner HP LaserJet 416A Yellow (W2042A) Original

- Toner HP LaserJet 119A Cyan W2091A Original

Selamat berbelanja, Shopper!

Frac Tank Cleaning and Maintenance Is Essential

Diposting pada 17 October 2015 oleh support | Dilihat: 261 kali

Many drilling companies engage in a practice known as fracking, which involves drilling and cracking into a layer of rock underground to get to a natural resource. It can be oil, natural gas, coal or really any fossil fuel that can be found. This is usually done with pressure from fluids. These frac tanks hold over 20,000 gallons of fluid, often times water that is used for hydraulic fracturing. Frac tanks actually look like very large, on site storage containers that individuals and companies can rent to store materials. That’s what they essentially are, only they are holding fluids and they must not leak. These requirements mean that these large storage container shaped tanks must be properly maintained to avoid rust and breaches in the container itself.

Like all equipment involved in drilling for fossil fuels, frac tanks get extremely dirty and have to be cleaned on a regular basis. This can be from the fluid held in the tank that was used for fracking, caked on mud, oil sludge, grease and various other debris that eventually found their way onto the frac tank from a drilling or mining operation. Typical household cleaners aren’t always suited for this type of job. Companies usually utilize industrial strength degreasers to effectively clean their frac tanks. Paired with a pressure washer, they can usually clean their tank to government specifications in a timely and economical manner.

Due to the rather controversially destructive nature of this type of drilling and it’s impact on the landscape, which involves damaging layers of rock, cleaning companies often try to use environmentally friendly, biodegradable, non regulated degreasers to clean the tanks. This appeases the masses and is usually safer for the work force in general as opposed to using highly caustic cleaners which can be dangerous to work with over extended periods of time. Even the most mild industrial cleaners still must be used with caution. Power washer operators usually wear protective goggles, gloves and sometimes masks to protect themselves from any vapor or splatter resulting from blasting the tanks clean.

In conclusion, frac tank maintenance is an essential part of drilling companies operations. It is far more economical to maintain a tank because the cost of having to constantly buy new tanks due to neglect is much higher than buying chemicals and cleaning them on a continual basis. Companies may also outsource the work to third parties who specialize in frac tank cleaning.

Bagikan informasi tentang Frac Tank Cleaning and Maintenance Is Essential kepada teman atau kerabat Anda.

Frac Tank Cleaning and Maintenance Is Essential |

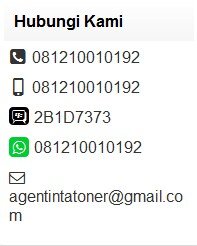

*Pemesanan dapat langsung menghubungi kontak di bawah ini:

*Harga Hubungi CS

*Harga Hubungi CS *Pemesanan dapat langsung menghubungi kontak di bawah ini:

*Harga Hubungi CS

*Harga Hubungi CS *Pemesanan dapat langsung menghubungi kontak di bawah ini:

*Harga Hubungi CS

*Harga Hubungi CS

Belum ada komentar untuk Frac Tank Cleaning and Maintenance Is Essential